By operating our assets safely, reliably and with consideration for the environment, we contribute to the long-term success of our employees, communities, customers and investors.

At Pembina, we take a lifecycle approach to managing our assets including planning, construction, operation, decommissioning and reclamation activities. We are committed to continuously improving our operations and seek to align our operating practices to leading standards.

Pembina's view of responsible asset management includes the following topic areas: Asset Management, Emergency Preparedness & Response, Waste & Water Management, Biodiversity & Land Use and Cybersecurity.

Operational Excellence Management System

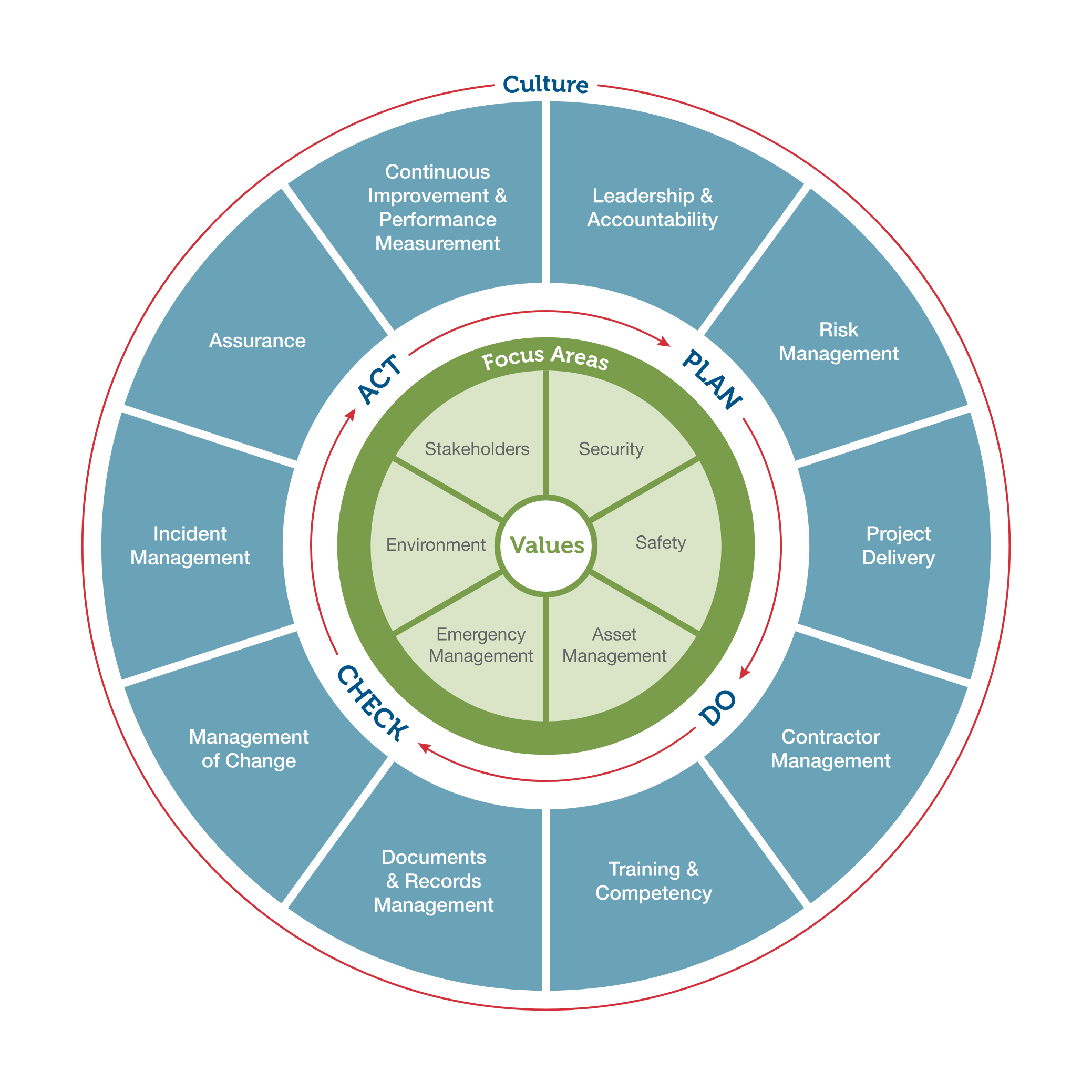

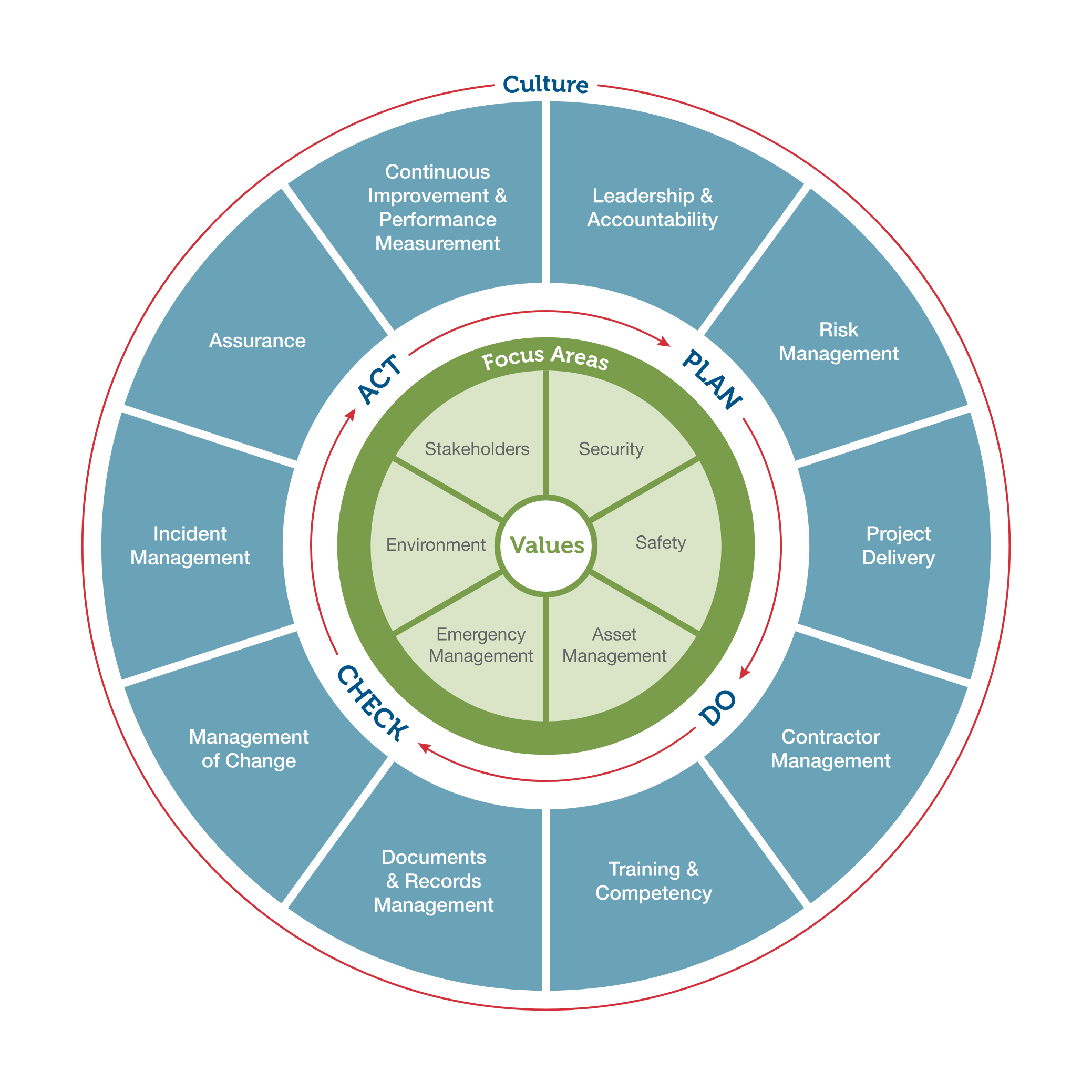

As a company, we are committed to Operational Excellence, which means placing the highest value on the health and safety of our workforce, the protection of our assets and the environment. Pembina’s Operational Excellence Management System (“OEMS”) executes on this commitment by applying risk management, processes, procedures, and accountabilities to document a consistent approach to the way we operate.

The OEMS is a continuous improvement framework incorporating the Plan-Do-Check-Act Cycle supported by policies, programs, processes and procedures to guide planning, implementation, checking and corrective action. OEMS addresses operational risk through leadership, risk identification and assessment, expectations and responsibilities and continuous improvement.

Pembina's OEMS comprises programs that promote safety, reliability, efficiency, cost-effectiveness and continuous improvement. At its core are our values: safe, trustworthy, respectful, collaborative, and entrepreneurial. These values shape our behaviour and guide our strategic goals. Operational improvements and industry changes are assessed, prioritized and addressed through corrective and preventative actions using the Plan-Do-Check-Act Cycle. By leveraging our OEMS, we foster a culture of compliance, efficiency, effectiveness and continuous improvement, driving operational excellence.

Pembina's OEMS comprises programs that promote safety, reliability, efficiency, cost-effectiveness and continuous improvement. At its core are our values: safe, trustworthy, respectful, collaborative, and entrepreneurial. These values shape our behaviour and guide our strategic goals. Operational improvements and industry changes are assessed, prioritized and addressed through corrective and preventative actions using the Plan-Do-Check-Act Cycle. By leveraging our OEMS, we foster a culture of compliance, efficiency, effectiveness and continuous improvement, driving operational excellence.

Pembina's OEMS comprises programs that promote safety, reliability, efficiency, cost-effectiveness and continuous improvement. At its core are our values: safe, trustworthy, respectful, collaborative, and entrepreneurial. These values shape our behaviour and guide our strategic goals. Operational improvements and industry changes are assessed, prioritized and addressed through corrective and preventative actions using the Plan-Do-Check-Act Cycle. By leveraging our OEMS, we foster a culture of compliance, efficiency, effectiveness and continuous improvement, driving operational excellence.

Pembina's OEMS comprises programs that promote safety, reliability, efficiency, cost-effectiveness and continuous improvement. At its core are our values: safe, trustworthy, respectful, collaborative, and entrepreneurial. These values shape our behaviour and guide our strategic goals. Operational improvements and industry changes are assessed, prioritized and addressed through corrective and preventative actions using the Plan-Do-Check-Act Cycle. By leveraging our OEMS, we foster a culture of compliance, efficiency, effectiveness and continuous improvement, driving operational excellence.